Why airRoxy?

The airRoxy products are designed using the newest technological capabilities and taking into account the prevailing trends. Therefore, not only do they look modern, but also a number of innovative solutions have been applied.

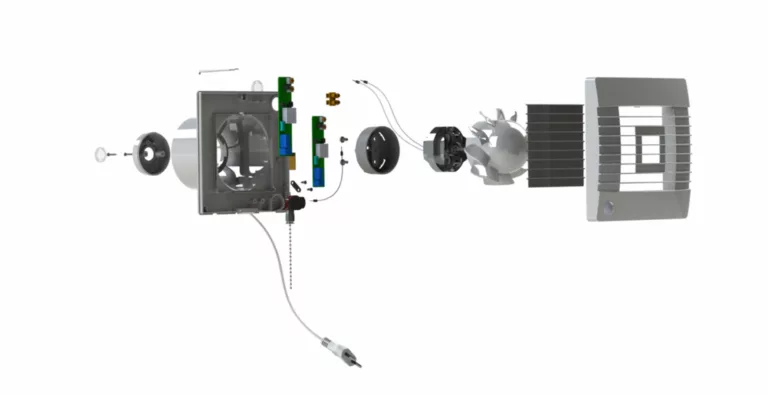

Using the modular construction and production unification, give us the flexibility in modifying the electronic controllers both with the direct or alternating current sensors, and turbines. As a result, our products allows to adapt to customers needs.

Only airRoxy fans, among all the competitors offer, have the turbines with changeable paddle geometry. It gives a large airflow with low acoustic pressure. Moreover, our fans have fan baffle which improves the airflow even more.

Production only from the original plastic, gives 100% repeatability of injection molding with a uniform white color, and the use of volumetric dispensers with a mixer allows to maintain full repeatability of other colors. Closed-loop production using robots and mills allows 100% material utilization, resulting in an attractive price without compromising quality.

Our fans are tested with three measurement methods, which gives the most precise results. Thanks to the used materials, and innovative technologies our fans reach high performance with low noise level.

Three-stage quality control, first during injection molding, then during assembly and packaging, and finally inspection of the finished product ensures a low complaint rate of 0.1%.

Production follows defined procedures based on the issued product certificate TUV SUD production monitored.

The casing of the fans is made of the best quality ABS with antistatic addition and UV stabilizers. It prevents the fans from dust accumulation, and guarantees snow white colour for many years. Active elements exposed to the high temperature are made of technical material called polycarbonate. It makes the usage safer and it prolongs the operating life of the fan. Silicon seals and a special casing construction of the fan ensure high class of waterproofness.

A number of improvements have been made to make installation and operation easier. Among them are: a leveling hole in the fans, which allows the fan to be installed perfectly straight by one person. Removable fronts, mounted with a click – without the need for tools and adhesives improve cleanliness and facilitate access to control and cleaning without dismantling the unit.